LB-III LABEL WEAVING MACHINE

product details

·Harness

Material: ITALY&KOREA

|

SX-1152 |

SX-2304 |

| 8 Repeats for teffeta(1 repeat=20cm MAX) | 4 Repeats for teffeta(1 repeat=40cm MAX) |

| 16 Repeats for satin(1 repeat=10cm MAX) | 8 Repeats for satin(1 repeat=20cm MAX) |

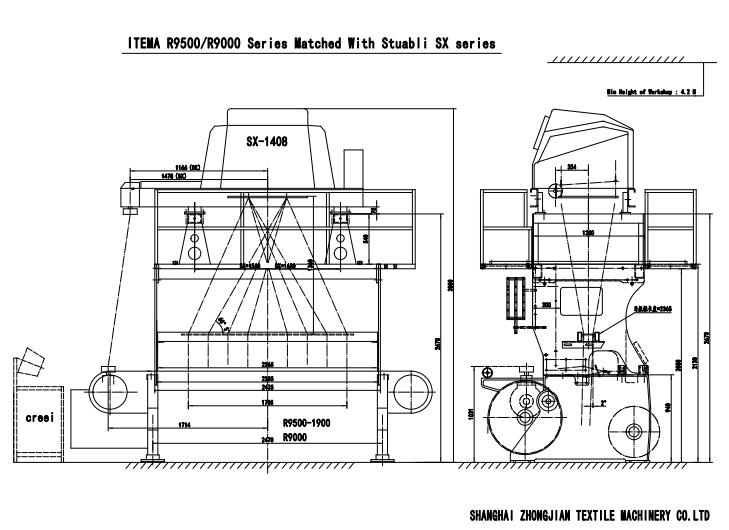

·Loom

ITEMA R9500

Loom width :1900mm

Working width:1678mm

Speed :600MAX

Number of colours:8 colours/on request 12 colours mode

take-up & let-off motion:Electronic

Direct drive motor:Wlectronic Hi-drive brushless motor technology,providing added value by

fewer spare parts and maintenance free,with no cooling system required and

simple input desired setting via user interface

Weft yarns : Polyester from 50 den to 800 den;other yarns also on weaving

Warp yarns : Polyester 30 den to 150 den

Warp density :54.6-109.2 ends per cm

Beam:800mm

cloth roller : 600mm

·Hot cutting &pressing system

hot cut system: Electranic control system for hot cut

pressin system: air cylinder system for the pressin

Cutting System-Control box:Touch Panel

thremal cutter distance:1mm or 0.5mm(for narrow label)

Temperture Control:Auto adjustment in relation to speed

| COMPARISON TABLE FOR LABEL WEAVING MACHINE | |||||||

| TOPICS | ZHONGJIAN-I LABEL MACHINE | ZHONGJIAN-II LABEL MACHINE | ZHONGJIAN-III LABEL MACHINE | ||||

| Jacquard | Jacquard brand | ZHONGJIAN | STOUBLI | STOUBLI | |||

| Jacquard model | GES | DX | SX | ||||

| Jacquard hooks NO. | 1152 | 2304 | 1152 | 2304 | 1152 | 2304 | |

| Mechanical | 1)Driven by extremely solid bilateral eccentric cam | 1)Kinematics:Optimized moving parts are precisely balanced and linked without play to ensure weaving at high speed | 1)Kinematics:Optimized moving parts are precisely balanced and linked without play to ensure weaving at high speed | ||||

| 2)Equipped with the balance-arm lifring mechanism which eliminates unbalanced load and can work without vibration | 2)Balanced guiding:This high-percision system of arms and needle bearings ensures perfect liner guid-ance of the knife frames and enhances the service life of the machine | 2)Balanced guiding:This high-percision system of arms and needle bearings ensures perfect liner guid-ance of the knife frames and enhances the service life of the machine | |||||

| 3)Equipped with the solid lifting mechanism,supporting structure and the needle-selecting system which can work normally in high speed | Adjustment:Quick easy shed adjustment to support optimal effciency of the weaving mill | Adjustment:Quick easy shed adjustment to support optimal effciency of the weaving mill | |||||

| Module | M5 module with bearing with quick link | M6.2B module with bearing with quick link | M6.2B module with bearing with quick link | ||||

| Electranic controller | ZJ-III controller | JC7 controller | JC7 controller | ||||

| can work for JC5 and EP program both | Integrated design editor | Integrated design editor | |||||

| High Memory to stock the design | Dedicated filters for harness optimization | Dedicated filters for harness optimization | |||||

| Can setting the quantity label,after reach,then stop | Electronic false selvedge motion settings | Electronic false selvedge motion settings | |||||

| Can continuer the next design auto | Scheduled maintenance assistance:oil change and filter cleaning or replacement | Scheduled maintenance assistance:oil change and filter cleaning or replacement | |||||

| Reversal design | enhanced diagnostics | enhanced diagnostics | |||||

| Harness | Material | ITALY&Korea | ITALY&Korea | ITALY&Korea | |||

| Assembling | China | China | China | ||||

| Repeats | 8 Repeats for teffeta(1 repeat=20cm MAX) | 4 Repeats for teffeta(1 repeat=40cm MAX) | 8 Repeats for teffeta(1 repeat=20cm MAX) | 4 Repeats for teffeta(1 repeat=40cm MAX) | 8 Repeats for teffeta(1 repeat=20cm MAX) | 4 Repeats for teffeta(1 repeat=40cm MAX) | |

| 16 Repeats for satin(1 repeat=10cm MAX) | 8 Repeats for satin(1 repeat=20cm MAX) | 16 Repeats for satin(1 repeat=10cm MAX) | 8 Repeats for satin(1 repeat=20cm MAX) | 16 Repeats for satin(1 repeat=10cm MAX) | 8 Repeats for satin(1 repeat=20cm MAX) | ||

| Loom | Brand | ITEMA | ITEMA | ITEMA | |||

| Model | R9000 | R9500 | R9500 | ||||

| Loom width | 1900mm | 1900mm | 1900mm | ||||

| Working width | 1678mm | 1678mm | 1678mm | ||||

| Speed | 520RPM | 500RPM | 550RPM | 530RPM | 600RPM | 570RPM | |

| Number of colours | 8 colours/on request 12 colours mode | 8 colours/on request 12 colours mode | 8 colours/on request 12 colours mode | ||||

| Let-off | Electronic let-off motion | Electronic let-off motion | Electronic let-off motion | ||||

| Take-up | Electronic take-up motion | Electronic take-up motion | Electronic take-up motion | ||||

| Direct drive motor | Wlectronic Hi-drive brushless motor technology,providing added value by fewer spare parts and maintenance free,with no cooling system required and simple input desired setting via user interface | Wlectronic Hi-drive brushless motor technology,providing added value by fewer spare parts and maintenance free,with no cooling system required and simple input desired setting via user interface | Wlectronic Hi-drive brushless motor technology,providing added value by fewer spare parts and maintenance free,with no cooling system required and simple input desired setting via user interface | ||||

| Stop motion | Electronic system | Electronic system | Electronic system | ||||

| Weft yarns | Polyester from 50 den to 800 den;other yarns also on weaving | Polyester from 50 den to 800 den;other yarns also on weaving | Polyester from 50 den to 800 den;other yarns also on weaving | ||||

| Warp yarns | Polyester 30 den to 150 den | Polyester 30 den to 150 den | Polyester 30 den to 150 den | ||||

| Warp density | 54.6 per cm | 109.2 per cm | 54.6-109.2 ends per cm | 54.6-109.2 ends per cm | |||

| Beam | 800mm | 800mm | 800mm | ||||

| cloth roller | 600mm | 600mm | 600mm | ||||

| Hot cutting &pressing system | hot cut system | Electranic control system for hot cut | Electranic control system for hot cut | Electranic control system for hot cut | |||

| pressin system | air cylinder system for the pressin | air cylinder system for the pressin | air cylinder system for the pressin | ||||

| Cutting System-Control box | Touch Panel | Touch Panel | Touch Panel | ||||

| thremal cutter distance | 1mm(min) | 1mm or 0.5mm(for narrow label) | 1mm or 0.5mm(for narrow label) | ||||

| Temperture Control | Auto adjustment in relation to speed | Auto adjustment in relation to speed | Auto adjustment in relation to speed | ||||